|

|

The Mica powder can be used in the following ways:

For Fusing/Slumping:

Usually only used by the glass beadmakers, this is an attractive product that can be used on fused glass pieces to great effect. The metallic colors add highlights to a piece at minimal cost. There are several ways to use this powder. It is suitable for use on any type of glass, both soft and float. If you want to make it into a paint consistency, it needs to be mixed with a water based medium, such as Klyr Fire or Water Friendly Medium, and water, till desired consistency for technique being used. This mixture should be dense enough to have a good layer adhering to the glass before firing. Use plenty of the medium, as this is what helps to 'stick' the powder to the glass when it dries. The rule of thumb is "what you see is what you get". Test your mixture on a scrap of glass and let it dry. If the color is very pale, add more powder to the mix. If it dries very dull and 'scummy' looking, thin down a touch. Fire the piece to fusing temperature to get the powder to 'stick.' This is an inert material, and only what is in direct contact with the glass surface will stay on after firing, the rest will brush away. This is why a good mixture needs to be made with the painting medium to help this process. It is also fine for air-brushing onto the front OR back of the glass. Being inert, it will NOT stick to the kiln wash on the shelf or mould! Mix with the medium till correct consitency for spraying. On the top surface of the glass, it leaves a soft semi matt metallic coating, on the back a subtle "mirror" like effect, depending on the color. Once again, dust off what does not adhere in the firing process, and store for re-use. If you want to paint a design between 2 pieces of glass, care should be taken to make sure there is still enough unpainted glass to fuse to the base glass. The powder acts as a separator, and prevents the 2 layers from fusing if coated all over. Remember to burn off the paint medium before placing the 2 pieces together! Gases from the burning off could be trapped between the layers if this is not done. The powder can also be sprinkled onto the glass, but again, only what is touching the surface will stick, dust the rest off after firing for using again. Hair spray can be used to help the powder stick while you are working on the decoration. It can also be mixed with clear enamel powders or powdered frit and sifted over the glass. It is advisable to test the different colors first to make sure you get the results you are looking for. Various techniques of using this product are shown on the Dragon Glass instructional videos, "Answers, Ideas and Troubleshooting Kiln Fired Glass."

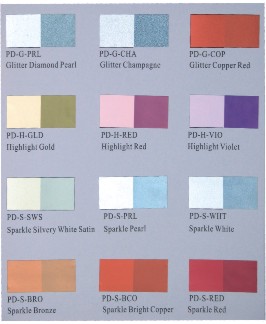

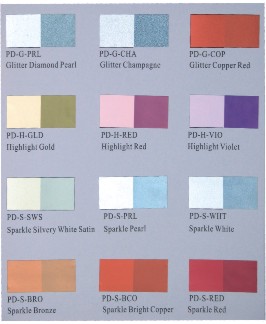

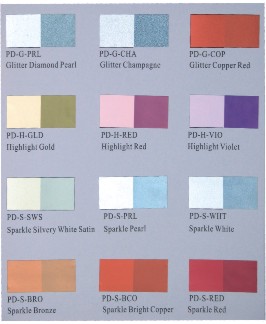

Color Chart

Mica Color Click On Photo For Large View |

|

For Glass Blowing:

Gather clear and roll hot glass in Mica powder. Heat piece in glory hole. Excess powder which has not melted on surface of the glass can be removed by dipping the piece in water or by scraping it off with the flat surface of the jacks. Gather more clear glass. At this point you can create colored sparkles by applying a layer of transparent color over the initial gathers.

If you want a layer of sparkles over a color it is best to case the color in clear before applying the Mica powder.

Mix Mica powder with your glass and apply to the exterior of the piece.

Sift Mica powders into a carbonized mold to get a pearlescent finish on your sand castings.

Also it is probably a good idea to sift the powder on some thing other than the marver since it easily becomes airborne and also sticks to metal.

|

|

|

For Beadmaking:

Use Mica Powder to create a sparkle or pearl luster color inside glass or on its surface.

To use, form glass to its final shape. Allow the glass to harden but, still remain hot. Quickly heat the surface of the glass until molten. Avoid allowing the inside of the glass to become molten or it will probably loose its shape during some of the following application methods. Any of the following methods can be used to apply Mica powder. Pile Mica Powder onto a metal or graphite work surface. Dip the glass into the powder and rotate it around until the glass is covered. The powder will only permanently adhere to molten glass. If you find that the powder did not adhere to the glass, it was not hot enough. The glass will coat with a thick layer of powder, but only the layer of powder that is in actual contact with the molten glass will adhere. The rest will be loose. Put the glass back into the flame to flame anneal it. Only use the cool end of the flame or the powder will burn onto the surface of the glass and the item will probably be ruined. Another application method is to place the powder into a small metal bowl or cup. Apply the powder by inserting the glass into the bowl. Because Mica Powder is made of mica, it is an excellent insulator. While the glass is engulfed in the powder, it performs a pseudo kind of flame annealing. You can also apply the powder by sprinkling or sifting it onto the glass. An enamel sifter works well. Sprinkling or sifting is the best method when you only have a small amount of powder to work with.

To encase glass that has just been coated, wipe off excess layers of powder first. Use a dry cotton cloth and wipe with a quick motion. Be careful with how you handle the cloth and where you put it, because it will get very hot and may catch fire. If you attempt to apply glass on top of the powder without wiping off the excess layers, the glass will just fall off, because it will only have stuck to the outside layer. Mica Powder that is encased is protected from the flame and will not burn. The color of the glass that the Mica Powder is applied to affects the final look. You can do a quick color test by simply coating the end of a glass rod. Even if you do not encase the glass after coating it, you can wipe off the excessive layers of powder to see if the application was successful.

You can also make a glass rod with Mica Powder dispersed throughout it. Heat up a quantity of glass until molten. Mash it flat. In the center of the flattened glass, place a small amount of Mica Powder. Without spilling the Mica Powder, heat the opposite side of the glass in the flame until it becomes soft and pliable. Carefully fold the glass, trapping the Mica Powder and sealing it in and away from possible direct contact with the flame. Do this while forcing out as much air as possible. Using the glass rod that the original flattened glass came from, as a punty, and another glass rod, mix the glass in the flame until well blended. Pull out into a rod.

Glitter Series |

|

Code |

Description |

PD-G-WHT |

Glitter Diamond White |

PD-G-PRL |

Glitter Diamond Pearl |

PD-G-CHA |

Glitter Champagne |

PD-G-GLD |

Glitter Gold |

PD-G-BRO |

Glitter Bronze |

PD-G-COP |

Glitter Copper Red |

|

|

Highlight Series |

|

Code |

Description |

PD-H-GLD |

Highlight Gold |

PD-H-RED |

Highlight Red |

PD-H-VIO |

Highlight Violet |

PD-H-BLU |

Highlight Blue |

PD-H-GRE |

Highlight Green |

PD-H-MGR |

Highlight Medium Green |

|

|

Sparkle Series |

|

Code |

Description |

PD-S-SWS |

Sparkle Silvery White Satin |

PD-S-PRL |

Sparkle Pearl |

PD-S-WHT |

Sparkle White |

PD-S-AGL |

Sparkle Aztec Gold |

PD-S-BGO |

Sparkle Bright Gold |

PD-S-GLD |

Sparkle Gold |

PD-S-BRO |

Sparkle Bronze |

PD-S-BCO |

Sparkle Bright Copper |

PD-S-RED |

Sparkle Red |

PD-S-FPU |

Sparkle Fruit Punch |

PD-S-GBR |

Sparkle Greenish Brown |

PD-S-RBR |

Sparkle Reddish Bronze |

|

|

Chart & Assorements |

|

Code |

Description |

PD-A-005 |

Assortment Pack 24 Color * 5 gm |

PD-A-030 |

Assortment Pack 24 Color *30 gm |

PD-A-200 |

Assortment Pack 24 Color *200 gm |

PD-CHART |

Color Chart of all 24 Colors |

To order, add the following after the part number to designate the size:

-005 for 5 gram bag

-030 for 30 gram jar

-200 for 200 gram jar

Example: PD-G-GLD-030 is a 30 gram jar |

|

• Splitters & Arrestors

• Splitters & Arrestors • spark lighters

• spark lighters  • digital pyrometers

• digital pyrometers  • SHEARS

• SHEARS • mica powder

• mica powder  • HOSES

• HOSES • caliper

• caliper • Price List

• Price List  • jUST FOR FUN

• jUST FOR FUN